In the world of corrugated packaging, speed and accuracy matter. Companies want strong boxes, neat edges, and a quick turnaround. That’s where Masterwork makes a real difference. This name has become known for building machines that keep up with busy workdays and get the job done right, every time. Corrugated die cutting isn’t simple. It takes power, precision, and a smart setup. Masterwork, a corrugated die cutting machine manufacturer, machines handle all of that without making things harder for operators. They’re built for real work in the real world—strong, fast, and easy to use.

Designed for Big, Tough Jobs

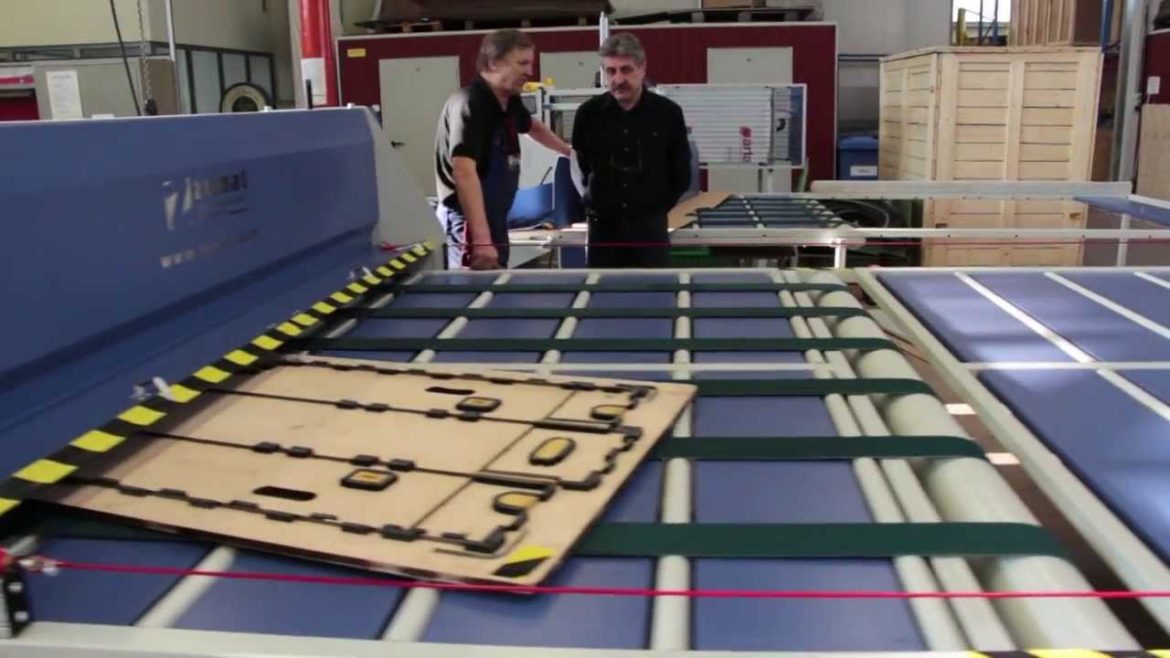

Masterwork machines are designed to handle heavy, thick sheets of corrugated board. Whether it’s single sheets or multi-layered boards, they cut clean and keep moving. The design accommodates large sheets, allowing for more to be cut in a single run. This saves time and reduces waste. The machines don’t just handle thick materials—they do it well. The cutting stays sharp and smooth, even after long shifts. The feeding system keeps everything in line, so no sheet goes crooked. That kind of control means fewer errors and better boxes.

Speed That Doesn’t Sacrifice Quality

It’s one thing to move fast. It’s another thing to maintain high quality while doing it. That’s something Masterwork machines are good at. They can hit speeds up to 6,000 sheets per hour, all while holding tight accuracy. Each machine has features that help speed up the process without compromising precision. Quick-lock tools and easy-change plates help reduce setup time. That means less downtime between jobs and more output every day. For factories and shops with big orders, this balance of speed and quality makes a real difference. It helps keep production flowing and customers happy.

Built to Last, Built for Work

A Masterwork die cutting machine isn’t just fast—it’s tough. These machines are built with strong parts and designed to last for years. From the heavy-duty frame to the smart design of moving parts, everything is made to handle long hours and hard work. The machines also keep things safe and steady. With careful controls and clear layouts, operators can do their jobs without confusion. That means better focus, smoother runs, and fewer mistakes. This kind of build quality also saves money over time. A strong machine means fewer repairs and less downtime.

Easy to Use, Easy to Learn

One of the best parts of a Masterwork machine is how easy it is to run. Even with all the power and features, the setup is simple. That makes it great for both new and experienced workers. Clear controls, smooth feeders, and fast-change parts mean less training time. Operators can get up to speed quickly, and they’re less likely to make costly mistakes. For busy teams, this matters a lot. The machines don’t demand too much. Instead, they help workers stay in control and keep things moving. That’s good for the people using them and good for business.

Flexible for Many Needs

Not every job is the same. Some need small runs. Others need thousands of pieces. Some boards are thick. Others are thin. Masterwork machines handle it all. They’re made to switch between different types of jobs without a full reset. That means a team can move from one order to the next without wasting time. Whether it’s a short run of custom boxes or a full day of high-volume work, the machine can take it. This kind of flexibility is rare, and it gives Masterwork a clear edge in the die-cutting world.

A Focus on Better Output

In the end, what matters most is what comes off the machine. With Masterwork, the results speak for themselves. Clean cuts, smooth edges, and tight shapes—all made to fit. Each sheet that runs through the system comes out ready to use. No fuss, no second tries. That kind of quality helps customers get their products out faster and look better. And it’s not just about looks. A clean cut means stronger folds, better stacking, and fewer damaged products. That’s a win for everyone.

Conclusion

Masterwork doesn’t just make die-cutting machines. It builds tools that solve real problems in busy workspaces. The machines are fast, smart, and simple to use. They’re strong enough to handle hard work and smart enough to stay efficient. What sets Masterwork apart is how well it blends power with control. Every feature is made to help teams do their best work—faster, safer, and with better results. For any company working with corrugated board, that kind of support goes a long way. In a world that moves fast, Masterwork gives teams the tools they need to keep up and stand out.